Fouling in Heat Exchangers

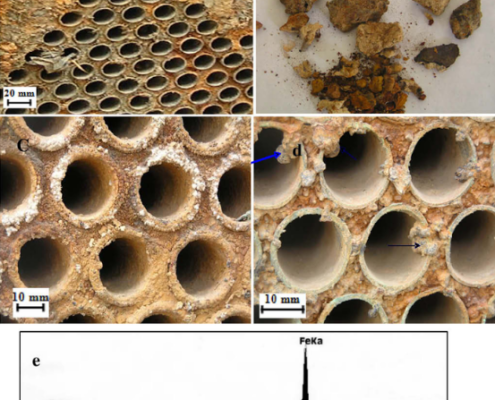

Fouling is the accumulation of unwanted material on solid surfaces of heat exchanger tubes affecting the heat transfer.

Main Features

- Obviates the need for Physical Cleaning of Heat exchangers

- Reduces Cleaning and Maintenance cost

- Reduces Frequent planned and unplanned shut downs

- Reduces capital cost of exchangers as the same can be designed for lower fouling resistance

- Easy and Faster to implement

- Very short pay back period

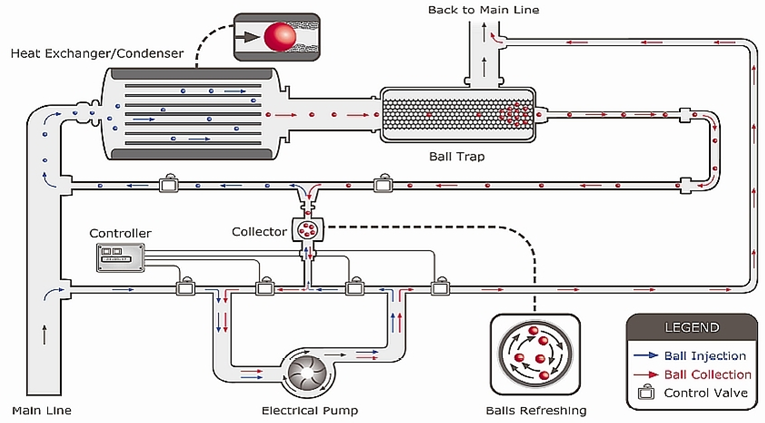

HOW IT WORKS

CAVITATION inside and out side the tubes disturb the boundary layer and the foulant film.

CAVITATION bubbles burst on the tube surface removing the foulant.

CAVITATION is created by propagation of sound waves.

CAVITATION strength is precisely designed as per the fluid characteristics and foulant.

CAVITATION is a Physical phenomenon occurring in Liquids when the static pressure is reduced below the liquid vapour pressure.

CAVITATION is created by propagation of sound waves in Liquid media through alternating Compression and rarefaction.

CAVITATION strength is determined by wave length of sound.