First ESCO directional Solvent extraction Process for Zero Liquid Discharge

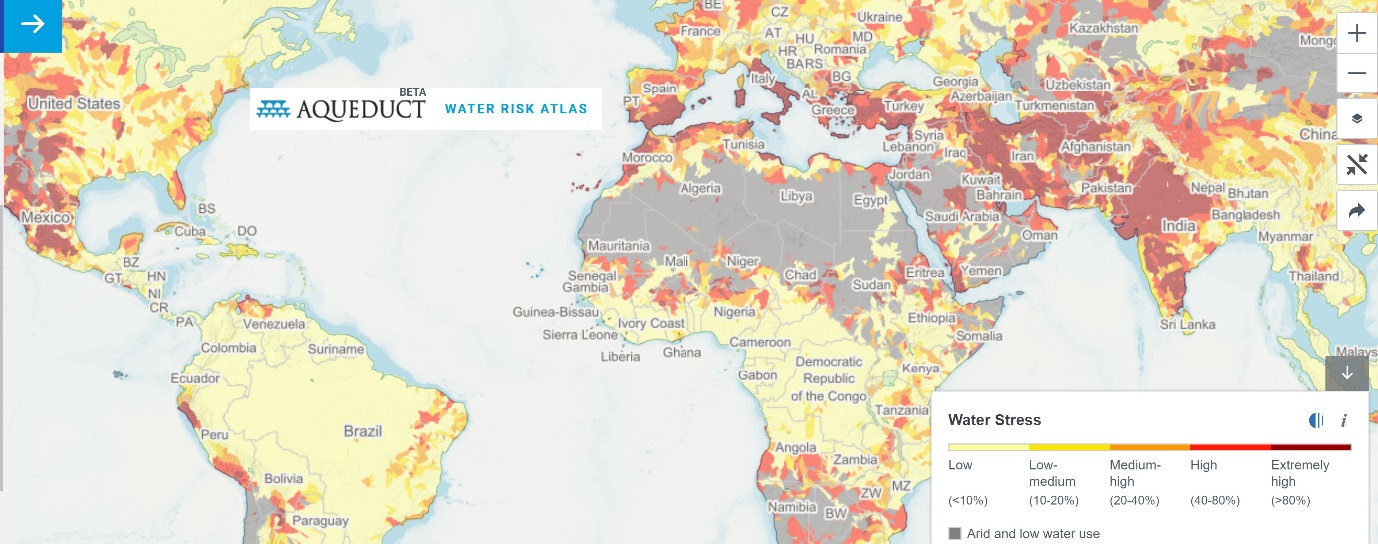

As per WRI ( World Resources Institute ) more than a billion people currently live in water-scarce regions, and as many as 3.5 billion people could experience water scarcity by 2025. Increasing pollution degrades freshwater and coastal aquatic ecosystems. As per the AQUADUCT project by WRI, India has been identified as a nation with extremely high water stress.

As per World Bank estimates current water use by industries accounts for 13% of all freshwater the Industrial water requirement is growing at 4.2% annually.

There is an urgent need for water conservation by Industries by adopting technologies for recycling industrial wastewater. ZLD ( Zero Liquid discharge ) is recommended by Environmental Agencies India as well as across the globe for water recycling and reuse. However conventional technologies for ZLD are highly energy-intensive as the ZLD process mainly consists of Evaporation and Crystallisation.

At FIRST ESCO we have developed a Proprietary process for ZLD using Directional solvent extraction. With this process, it is possible to remove all salts and contaminants and enable 100% water recycling with the least Energy requirement. The specific energy consumption for our process is 34 KWth/M3 of product water.

To know more about how we can help your Industry to achieve ZLD and 100% water recycling, check our presentation FE-DSE ZLD Process_11th Oct 20.